There is a desire for increased softness in all diaper components. To avoid diaper rash, breathable materials that let air through, are used more and more as well. in diapers. Yet, the landing zone is often a laminate that is not air-permeable. The laminate is often necessary to ensure convertibility in the diaper lines: the lines usually work with vacuum drums to guide the nonwoven loop areas, but open nonwoven is air-permeable, so harder to guide through vacuum systems.

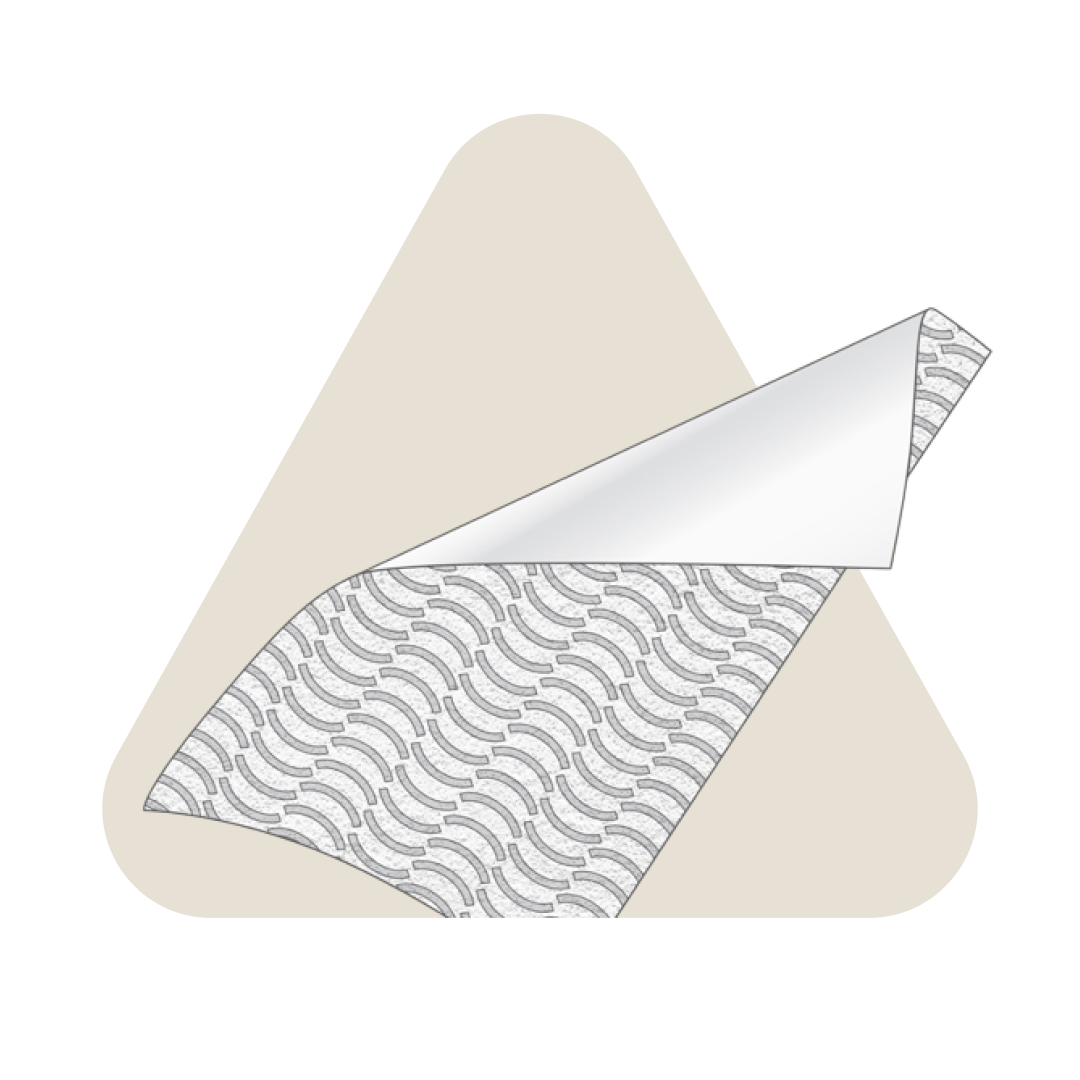

Mechanical closure systems are an industry standard, especially in developed markets. They need a loop-based landing zone. A hook tape and a landing zone need to be adapted to each other, to ensure optimal performance of the closure system, because your best hooks can still perform bad on a low-quality landing zone. Moreover, if the loops are easily damaged, you won’t be able to secure reclosability. With the change to mechanical closure systems in diapers, the cost of the closure system has increased. That evolution now points to nonwovens as loop material because of the much more interesting cost. Meanwhile, the market has accepted the change in performance and the machine equipment can now also convert this open type of material in a stable way.